SUNZDG series vacuum belt continuous dryer

Technology development background

Vacuum low-temperature automatic continuous dryer really have industrial value in the 70s of last century, the first batch of products using vacuum low-temperature automatic continuous dryer is maltose, produced by the British Scott and Balfour, in the mid 50s of last century, Wander and Sulzer co-developed the first Swiss vacuum belt dryer.

Sulzer in the 1960s the Taiwan vacuum cryogenic automatic continuous dryer sold in Zschokke, Dottingen, Switzerland, the original vacuum cryogenic automatic continuous dryer belt is composed of a metal belt. Until 1990, the company has been engaged in vacuum cryogenic automatic continuous dryer research, and in 1990 was taken over by Bucher, Germany in 1994 E & amp; E Merk company was established, and began to carry out different specifications of high-volume production. In 2007, Gemini cooperated with major universities and colleges and received advanced technical support from Germany. The company has a strong technical team. The Genetics Division of Gemini Company has successively set up bases for the experiment of major universities in China, national technology research and development platform, and more Home pharmaceutical biochemical, food processing plants provide multiple operating equipment.

Device Description

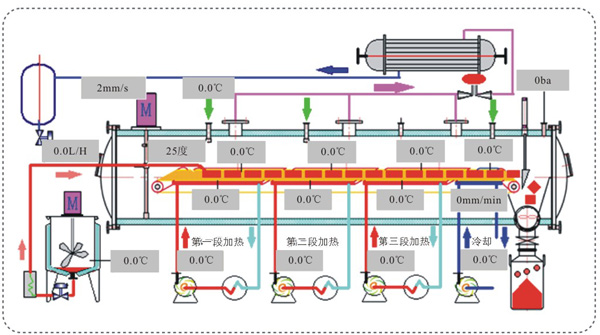

Vacuum low temperature automatic continuous dryer is a continuous feed, continuous discharge in the form of high degree of vacuum drying equipment, to be dried by the feed pump fluid into the high degree of vacuum within the dryer, the material is continuously delivered to the slow Moving dryer multi-layer drying belt, the drying belt in the speed motor driven at a set speed forward movement, each drying zone has three or more sections below the independent heating source and a cooling source, the material from When one end of the cylinder is moved to the other end, the material has been dried and cooled, the dried material is separated from the drying belt, the material is crushed by a crushing device, and discharged to the material bucket through the vacuum butterfly valve.

Dry material directly into the high vacuum container, after a period of time slowly drying (drying time: 30-60 minutes), after drying the resulting particles have a certain degree of crystallization effect, the internal micro-pore structure from the microscopic view. Directly crushed to the desired particle size, the particles flow well, you can direct compression or capsule, while the dry particles have a microscopic loose structure, excellent solubility. And the appearance of particles is good, for instant (granules) products, can enhance product quality.

Vacuum automatic track dryer to adapt to a wide range, for the vast majority of natural plant extracts, can be applied. Especially for high viscosity, easy clumping, thermoplastic, heat-sensitive materials, is not suitable or can not be spray-dried, vacuum automatic track dryer is the best choice. Moreover, the concentrated extract can be directly fed into a vacuum automatic crawler dryer for drying without adding any excipients, which can reduce the dosage of the final product and improve the product quality. Because of the high vacuum conditions, drying, drying temperature is lower, is conducive to maintaining the original color of the original extract. Vacuum automatic crawler dryer in one end of the fuselage continuous feed, the other end of the continuous discharge, the ingredients and the discharge part can be set in the clean room, the entire drying process is completely closed, not in contact with the external environment, in line with GMP requirements , Is the first choice for the modernization of Chinese medicine production equipment.

The unit is a continuous automatic drying equipment, especially for heat-sensitive, impatient mechanical pressure drying of the material, it can be widely used dry natural plant extracts, food processing and pharmaceutical products drying.

Vacuum belt drying has the following advantages: short drying time, small loss of aromaticity, no oxidation of the product, closed operating environment, small energy loss, control of the reaction process, low mechanical pressure during drying, superior instantaneous properties of the dried product, drying process Low drying temperature, no pollution to the environment, adjustable operating parameters.

working principle

Equipment Specifications

1, the type of dryer can be divided into; liquid continuous dryer and solid continuous dryer

2, dryer heating can be divided into: direct steam heating, superheated water heating, thermal oil heating.

3, dryer heating energy can be divided into: steam, electricity

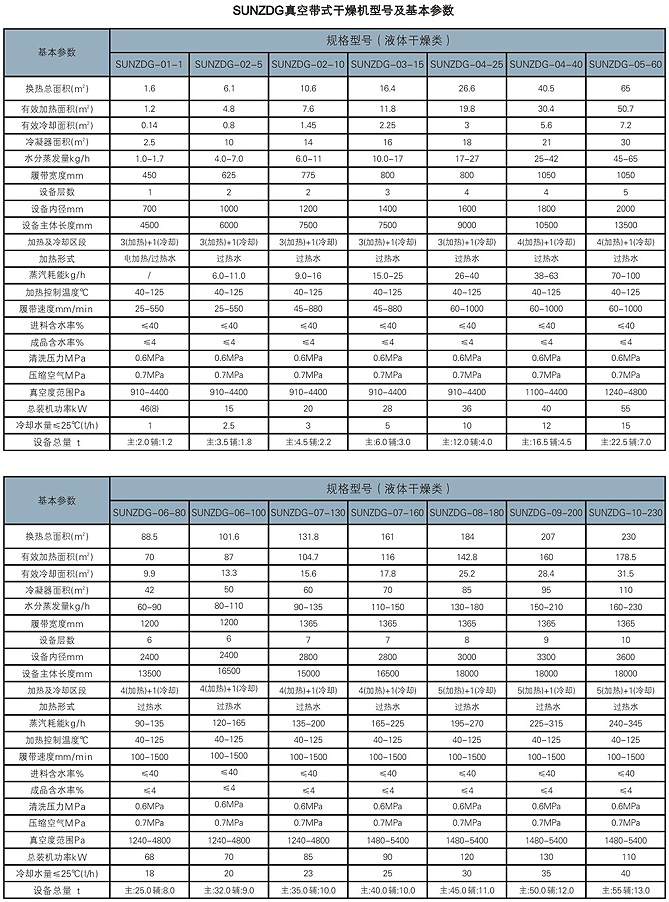

Zhejiang Twin Machinery Manufacturing Co., Ltd. already has a variety of models SUNZDG series of vacuum low-temperature automatic continuous dryer design and manufacturing capabilities for all industries to provide different production scale and the conditions of the corresponding equipment, to meet the needs of users. It is divided by specific types as follows:

1, according to the output of dry powder per hour design; 0.5Kg-500Kg

2, with the number of dry layer design: 1 layer -10 layer

3, according to equipment diameter and length design are: Diameter: φ 700mm- & 3600mm length; 4500mm-18000mm

Hotline:400-884-7779

Fax:0571-89197767

7th Tianhe Road, Yuhang Economic & Development Area, Hangzhou, China

copyright @ 2017 Zhejiang shuang zi Intelligent Equipment Co., Ltd