Products

WJG stainless steel reactor

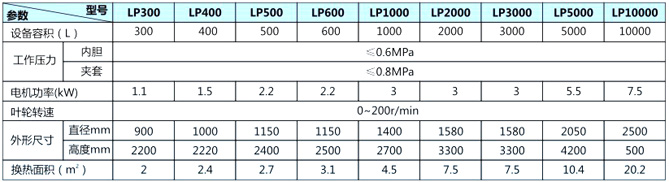

The equipment is commonly used as a reaction tank in industries such as pharmaceuticals, chemicals, and bioengineering. Structural features: 1. The device mainly consists of three parts: the cylinder, the jacket, and the outer shell. The space between the outer shell and the jacket is filled with high-density insulation material, and the top of the tank is equipped with a stirrer. 2. The pressure inside the jacket is determined according to customer requirements. 3. All materials are high-quality stainless steel. Overview: This series of containers is suitable for reactions in the chemical and pharmaceutical industries. The tank body can be made with honeycomb jackets, coil jackets, or integral jackets, and can be heated or cooled. The inner surface of the tank body is mechanically polished to a mirror finish, and the end caps are made by molding or spinning. All pipe openings and dead corners use R rounded transitions.

Classification:

Pharmaceutical Engineering (Western Medicine Equipment)

Keywords: new energy equipment, biological medicine equipment

INQUIRY

Product Description

Scope of Use

Commonly used as reaction tanks in industries such as pharmaceuticals, chemicals, and bioengineering.

Structural Features

1. The equipment mainly consists of three parts: the cylinder, the support, and the outer skin. The space between the outer skin and the jacket is filled with high-density insulation material, and the top of the tank is equipped with a stirrer.

2. The pressure inside the jacket is determined according to customer requirements.

3. All materials are high-quality stainless steel.

Overview

This series of containers is suitable for reactions in the chemical and pharmaceutical industries. The tank body can be made with honeycomb jackets, coil jackets, or integral jackets, and can be heated or cooled. The inner surface of the tank body is mechanically polished to a mirror finish, and the end caps are made by molding or spinning. All pipe openings and dead corners use R rounded transitions, fully complying with GMP requirements.

The stirrers can be anchor type, frame type, paddle type, or turbine type. The rotating mechanism can use cycloidal pinwheel reducers or continuously variable speed reducers. The sealing device can use mechanical seals, and heating and cooling can use jackets, half pipes, or coil structures. Heating methods include steam, electric heating, and heat transfer oil, to meet the process needs of different working environments such as acid and alkali resistance, high temperature resistance, wear resistance, and corrosion resistance.

Previous Page

Next Page

Previous Page

Next Page

Related Products

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.