Products

RCN Heat Reflux Vacuum Extractor Concentrator

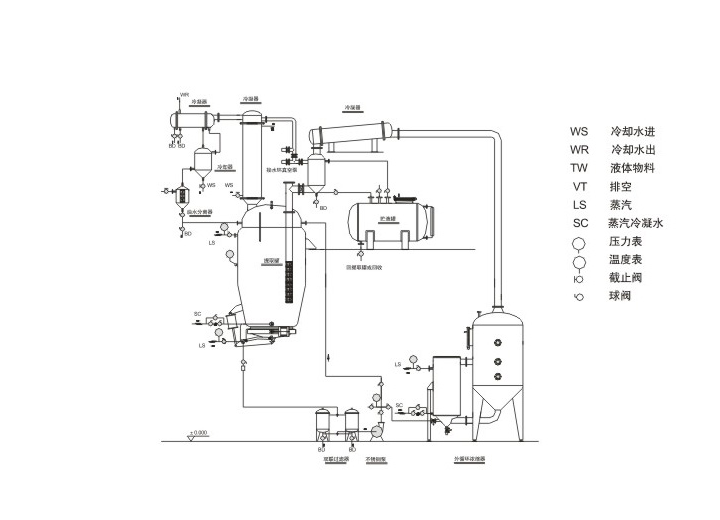

The vacuum extraction and concentration unit developed by our company has the following characteristics: 1. The concentration heating area is large, with high thermal efficiency, short concentration time, not easy to scale, and easy to clean. The unit has an intermediate storage tank for the extract, which is stored in the tank at the bottom of the evaporator. The extraction tank can discharge residue and prepare for the next batch of extraction. During this period, the concentrator completes the concentration of the extract and prepares for the next batch of extraction; 2. The extraction yield is increased by more than 8%, with high effective components. The extraction and concentration are completed in the same closed equipment, resulting in minimal loss. Due to the use of low-temperature extraction, the quality of the extract after concentration is high, with pure color, aroma, and flavor; 3.

Classification:

Plant and Traditional Chinese Medicine Extraction System

Keywords: new energy equipment, biological medicine equipment

INQUIRY

Product Description

RCN Heat Reflux Vacuum Extractor

1. Large heating area for concentration, high thermal efficiency, short concentration time, not easy to scale, easy to clean. The unit has an intermediate storage tank for the extract, which is stored in the lower tank of the evaporator. The extraction tank can discharge residue and prepare for the next batch of extraction. During this period, the concentrator completes the concentration of the extract and prepares for the next batch of extraction.

2. Increases extraction yield by more than 8%, high effective components, extraction and concentration are completed in the same closed equipment, with minimal loss; due to low-temperature extraction, the quality of the extract after concentration is high, with pure color, aroma, and flavor.

3. Large condensation area, conducive to the condensation and recovery of solvents, with minimal solvent loss and a recovery rate of over 95%.

4. Significant energy-saving effects, full utilization of waste heat, reduced repeated heating and cooling, greatly reduced energy consumption.

5. Multi-purpose machine, compact structure, small footprint, fewer operators, low investment costs, and low production costs.

6. Fully enclosed pipeline production, reducing environmental pollution, in compliance with GMP requirements.

Related Products

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.