Products

SUNZDG series vacuum belt continuous dryer

Background of Technological Development The true industrial application value of vacuum low-temperature automatic continuous dryers emerged in the 1970s. The first products produced using vacuum low-temperature automatic continuous dryers were maltose, manufactured by Scott and Balfour in the UK. In the mid-1950s, Wander and Sulzer collaborated to develop the first Swiss vacuum belt dryer unit. In the 1960s, Sulzer sold this vacuum low-temperature automatic continuous dryer to Zschokke in Dottingen, Switzerland. The original vacuum low-temperature automatic continuous dryer had a conveyor belt made of metal.

Classification:

Vacuum low-temperature drying equipment

Keywords: new energy equipment, biological medicine equipment

INQUIRY

Product Description

Background of Technological Development

The true industrial application value of vacuum low-temperature automatic continuous dryers emerged in the 1970s. The first products produced using vacuum low-temperature automatic continuous dryers were maltose, produced by Scott and Balfour in the UK. In the mid-1950s, the first Swiss vacuum belt dryer was developed through a collaboration between Wander and Sulzer.

In the 1960s, Sulzer sold this vacuum low-temperature automatic continuous dryer to Zschokke in Dottingen, Switzerland. The original vacuum low-temperature automatic continuous dryer had a conveyor belt made of metal. Up until 1990, the company was engaged in research related to vacuum low-temperature automatic continuous dryers, and in 1990 it was acquired by Bucher. In 1994, the German company E&E Merk was established and began large-scale production of various specifications. In 2007, the Gemini company collaborated with major universities, supported by advanced technology from Germany. The company has a strong technical team, and the drying division of Gemini has provided multiple operational devices to major domestic university experimental bases, national technology research and development platforms, and several pharmaceutical, biochemical, and food deep processing factories.

Equipment Description

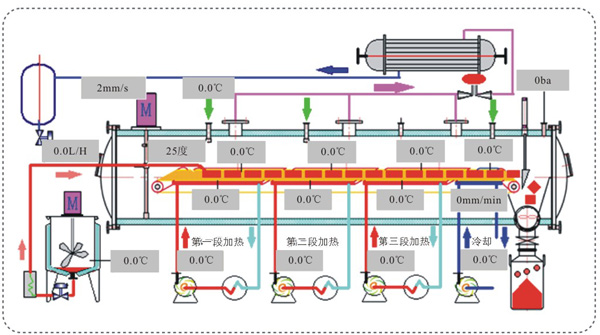

The vacuum low-temperature automatic continuous dryer is a high vacuum drying device with continuous feeding and continuous discharging. The material to be dried is pumped into the highly vacuumed dryer through a variable frequency screw pump. The material is continuously transported onto the slowly moving multi-layer drying belt inside the dryer. The drying belt moves forward at a set speed driven by a speed-regulating motor. Each drying belt has three or more independent heating sources and a cooling source underneath. As the material moves from one end of the cylinder to the other, it is dried and cooled. The dried material separates from the drying belt and is crushed by a crushing device before being discharged into a material barrel through a vacuum butterfly valve.

The dry material directly enters a high vacuum container and undergoes slow drying for a period of time (drying time: 30-60 minutes). The resulting particles have a certain degree of crystallization effect, and from a microscopic structure perspective, they contain micropores. After being directly crushed to the required particle size, the particles have good flowability and can be directly compressed into tablets or filled into capsules. Additionally, the dry particles have a microscopic loose structure, which provides excellent solubility. The appearance of the particles is also good, which can enhance the quality of instant (powder) products.

The vacuum automatic belt dryer has a wide range of adaptability and can be applied to the vast majority of natural plant extracts. It is especially ideal for materials that are highly viscous, prone to agglomeration, thermoplastic, and heat-sensitive, which are not suitable for or cannot be dried using spray drying. The vacuum automatic belt dryer can directly dry concentrated extracts without the need to add any auxiliary materials, thus reducing the dosage of the final product and improving its quality. Because drying occurs under high vacuum conditions, the drying temperature is relatively low, which helps to maintain the original color and flavor of the extract. The vacuum automatic belt dryer continuously feeds at one end of the machine and continuously discharges at the other end. The feeding and discharging sections can be set in a clean room, and the entire drying process is completely sealed, not in contact with the external environment, meeting GMP requirements, making it an ideal choice for the modernization and upgrading of traditional Chinese medicine production.

This unit is a continuous automated drying device, particularly suitable for drying heat-sensitive and mechanically fragile materials, and can be widely used for drying natural plant extracts, food deep processing, and pharmaceutical products.

Vacuum belt drying has the following advantages: short drying time, minimal loss of aroma, no oxidation of products, closed operating environment, low energy consumption, controllable reaction process, low mechanical pressure during drying, excellent solubility characteristics of dried products, low drying temperature, no environmental pollution, and adjustable operating parameters.

Working Principle

Equipment Specifications

1. The types of dryers can be divided into: liquid continuous dryers and solid continuous dryers.

2. The heating methods of the dryers can be divided into: direct steam heating, hot water heating, and heat transfer oil heating.

3. The heating energy sources of the dryers can be divided into: steam and electricity.

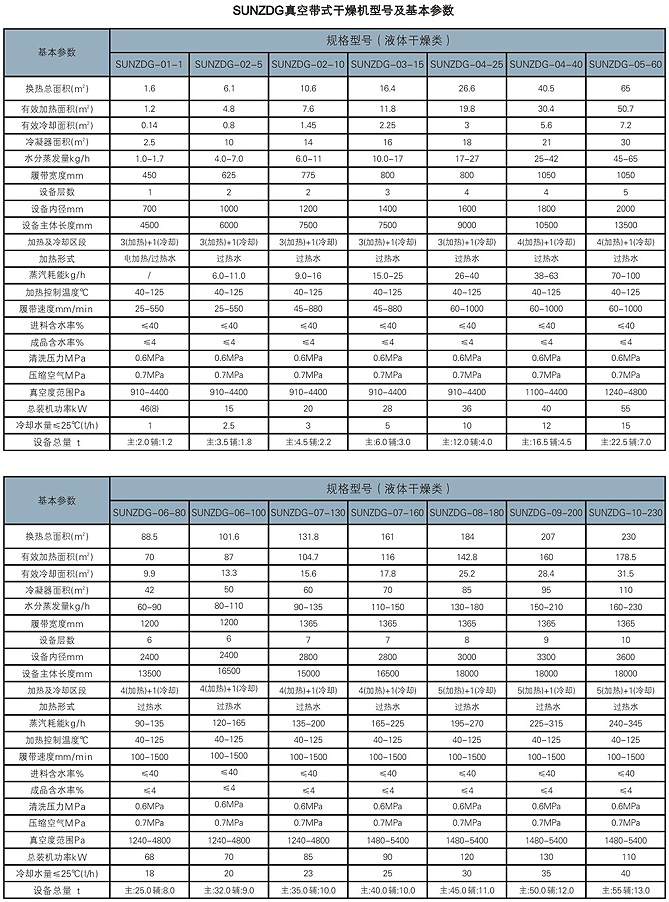

Zhejiang Gemini Machinery Manufacturing Co., Ltd. has the design and manufacturing capabilities for various models of the SUNZDG series vacuum low-temperature automatic continuous dryers, providing corresponding equipment for different production scales and working conditions in various industries to meet user needs. The classification is as follows:

1. Designed according to the hourly output of dry powder: 0.5Kg-500Kg.

2. Designed according to the number of drying layers: 1 layer - 10 layers.

3. Designed according to the diameter and length of the equipment: Diameter: φ700mm - φ3600mm; Length: 4500mm - 18000mm.

Previous Page

Related Products

ONLINE MESSAGE

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.